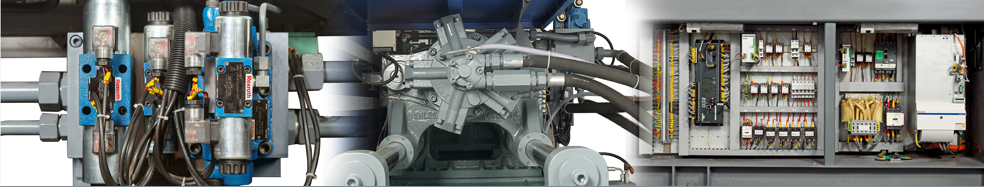

HYDRAULICS

- Energy saving servo Motor & Internal gear pump.

- Oil Temperature Gauge (Digital).

- Oil Level Gauge.

- Direct Reading Hydraulic Pressure.

- Compact And Easily Accessible Injection And Clamping Valves Manifold To Minimize The Heat Generation.

- Contamination Free Oil Tank with Feeler Cum-Breather.

- For Servo/VDP Machine Return Line Filter.

- Alarm/shut down for return filter clogging.

- Alarm/shut down for Low oil level (Hydraulic Tank)

- Alarm/shut down for Lubrication oil level low.

- Rear Gate open than Main motor shut down. (safety)

- Hydraulic Directional valve on/off indicator connector.

CLAMPING UNIT

- Heavy Duty 5-Point Double Toggle Mechanism With-Large Mold Opening Stroke.

- High Wear Resistance &High Strength Characters Gear Nut (Tie bar Nut) gives Rigid & Positive Clamping force.

- High Stiffness Platen Design with Large Mold mounting Area.

- Five Stage Mold Close/Open Speed (Slow-Fast Slow) & Pressure.

- Computer Aided Design Toggle Mechanism Gives Optimal Mold Closing And Opening Speed Profit.

- Multi Stage Digital Speed and Pressure Setting For Mold Closing And Opening.

- Ramping adjustment for accurate position.

- Linear Transducer for accurate clamp position.

- Mold protection with repeat again option.

- Travel time display for close & open.

- Hard-Chrome Plated High-Tensile Steel Tie-Bars with Stress-Relieve-Design.

- Auto-Mold Height Adjustment with Hydraulic Motor.

- Hydraulic ejector with multiple selection.(continues, shake, hold etc.)

- Auto-Lubrication as standard features for all models (shot adjustment).

- Linear Transducer ejector cylinder.

- Shaking ejector for multi-cavity mold.

- Less vibration & Jerks of machine(ramp adjustment).

- Large mould mounting area for producing large article specialy useful for pet preform, pipe fittings etc.

- Platen casting designed with finit element analysis for maximum rigidity.

- Hydrolic& electrical safety interlocks in moving platen movements for mould& operator safety.

- Mould platen wit t-slots(330 ton & above)

- All casting passed through stricke ultrasonic test and tensile testing process.

- Separate pressure & speed setting for mold set-up.

- High wear resistant skate-pad for heavy mold loading applicable for all models

- OilLess bushing with graphite impregnated for toggle mechanism given long life against wear out.

- Heavy-duty toggle design give trouble free precise clamping force for long period.

- Transparent vision on both safety door.

- Top fixed cover gives dust free clamping unit this give extra life to toggle mechanism.

- Anti-vibrating pads with stronger dampening.

INJECTION UNIT

- Gas Nitride Hardened Screw and Barrel for wear resistance and long life.

- Screw For Homogenous Plasticizing.

- Screw Back Pressure with pressure guage provision.

- High Torque Hydraulic motor for better plastification Screw Counter.

- 5 – Stage Injection Speed pressure & position control.

- 3 – Stage Injection holding speed pressure & position control.

- Hopper Sliding Arrangement for material removal.

- Electric Shot Counter.

- Cold slug eject by time.

- Intrusion molding program.

- Selection of Injection time & position both.

- Screw Tachometer (Digital RPM).

- Heater failure & thermocouple failure detection.

- High/low temperature alarm. (settable low-high limit)

- Auto heat start-up.

- Twin cylinder design. Dual nozzle centering precise thus contribute the longer life of mould.

- Linear potentiometer for injection/plasticizing.

- Auto purging facility.

- Suck back function and after plastizine suck back.

- Ceramic bands heaters for instant heating.

- Barrel heater safety cover.

- Nozzle centering alignment device.

- Nozzle contact force confirmation with the use of pressure switch.

CONTROL SYSTEM

- Energy meter

- Multi password facility for operators.

- Energy meter on panel door.

- M.C.C.B. For Main.

- Separate SMPS for CPU and servo drive.

- Star Delta Motor Starter For (N100 & Above).

- Digital Setting Timers.

- M.C.B. On Each Heating Zone.

- PID Temp Controller for Accurate Control.

- Programmable Logic Control System with Led Input / Output Indicator for Simplified Checking.

- Digital Display Timer.

- Digital Display Shot Counter.

- MPCB for Motor Protection

- Pressure & Flow for All Individual Function Control by P.L.C. Or Microprocessor.

- Linear Scale for Injection, Clamping & Ejector Cylinder.

- Value change record page.

- Alarm history page.

- Printer interface with USB port.

- Connect with local PC via Ethernet port any no. of machine (easy-net) for remote diagnosis.

- Production/hour in vertical-bar for year.

- I/O replaceable onboard while any I/O short.

- Easy export/import of mold data & machine data.

- Press any key for onscreen help (related to controller).

- Injection cool prevent time settable.

- Panel cabinet high temperature shut-down.

- Power ON time

- Eltra electric power supply socket-single phase-01,three phase-01

- Hourly energy consumption statics page designed commercial calculation.(product cost calculation)

SAFETY FEATURES

- Hydraulic Safety on Both Front & Rear Door.

- Electric Mold Safety.

- Magnetic Grills in Hopper.

- M.C.C.B. on Main.

- Over Load Circuit Breaker.

- Under Voltage-Over Voltage Protection.

- Reverse Phase, Single Phase Protection.

- Machine lifting hooks provide as standard accessories.

OPTIONAL FEATURES

- Bi-Metallic Screw Barrel.

- Digital Back Pressure.

- Hopper Dryer.

- Hopper Loader.

- Hydraulic Core-Pulling and Unscrewing.

- Water Flow Regulator with Temperature Gauges.

- Running Hour-Meter.

- Special PVC Screw & High Dispersion Barrel.

- Mold Lifting Hanger with Pulley.

- Auto-Taker (Robot) Interface.

- Air-Ejector.

- Hydraulic oil

- Accumulator Design for Thin Wall-Thickness Component. Servo Drive Benefits While Machine Is In Ideal Condition (Cooling Time, Injection Holding Etc.)

- Close loop valve.

- Gas injection interface only up to digital output from control.

- Blowers with heaters for processing heat sensitive materials.

- Nozzle shut off provision.

- Hot runner temp controller with no. of zones and wattage capacity.

- Mould clamp & fastener.

- Water manifold.

- Extended nozzle with heater.

- Multiline water battery with temp. Indicator guard.

- Water sever valve.

- Ladder for loading material in hopper.

- Ejector in back position confirmation by limit switch

- Serial /USB (PC3 version) printer facility.

- Artificial intelligence facility.

- Parallel plasticizing with e drive for cycle time reduction.

- Remote monitoring of machine.